Cold Rolling

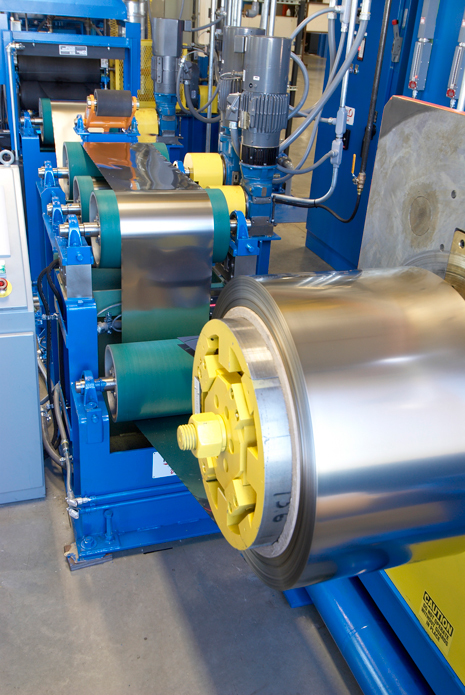

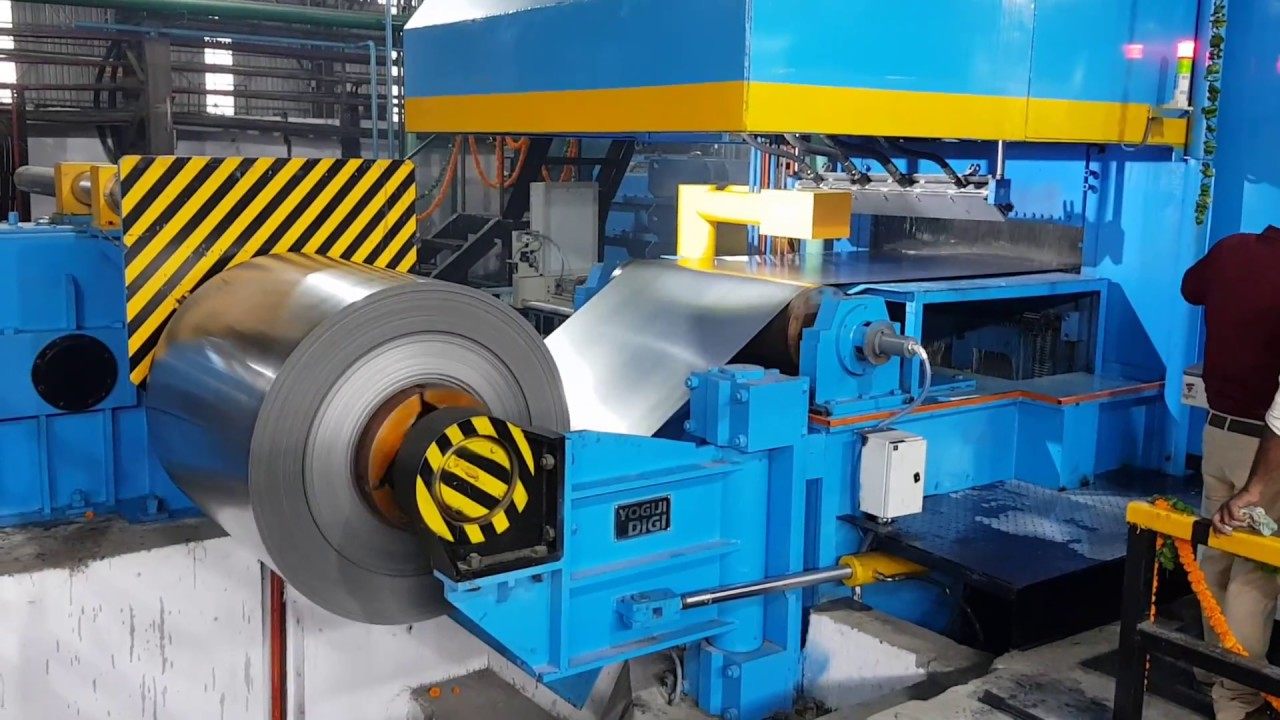

Cold Rolling Mills

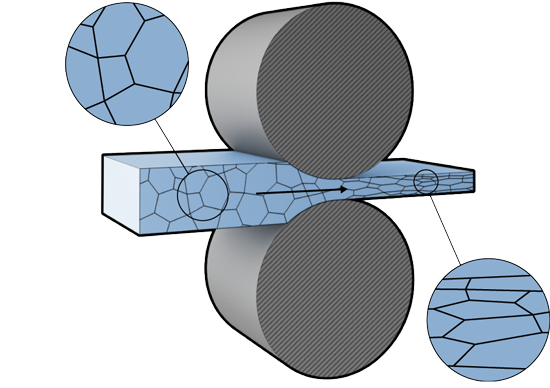

Cold rolling is a process by which metal is passed through rollers at temperatures below its recrystallization temperatures. The metal is compressed and squeezed, increasing the yield strength and hardness of the metal.

Cold rolling of metal strip is a special segment within the metalworking industry. The purpose of this process is to create thinner metal strips with a good dimensional accuracy and a dedicated surface quality for a variety of applications.

For the manufacture of steel strip that satisfies the strictest tolerance requirements at high productivity levels — for carbon, stainless, and special steel grades like AHSS (advanced high-strength steel) — a cutting-edge cold-rolling mill is necessary. Yangli World Links is able to provide fully optimized mill configurations that meet the unique needs of each customer because of its years of experience in the supply of cold-rolling mills and ongoing technological innovation.

What is Cold Rolled Stainless Steel?

Cold rolled steel, sometimes abbreviated to CRS, is well-known for being an extremely ductile material, and is ideal for applications where precision is necessary. It is used in many applications, like household appliances, furniture, lockers, and filing cabinets. In construction applications, CRS is commonly used for building garages, steel sheds, and other industrial buildings.

In simple terms, cold rolling is the process of strengthening steel by changing its shape without using heat. Cold rolling, unlike hot rolling such as with hot rolled steel, can only occur when a metal is below its re-crystallization temperature. Where hot rolling is performed using high temperatures, cold rolling is performed at room temperature. Instead of heat, mechanical stress is used to change the structure of metal. Strain hardening can then increase the metal's strength by up to 20%, and can also improve a metal's surface finish.

How Does a Cold Rolling Mill Work?

The process of cold rolling a metal alloy starts with either sheet metal or strip coil. These materials are placed into large rollers, which compress it down and squeeze it under high pressure just below its ultimate tensile strength. Depending on the amount of compression, different mechanical properties and hardness properties are achieved in the finished product. Through cold reduction, the thickness of the metal can be reduced by processing steel strip through a sequence of tandem rolling mill stands. The rolls on these stands are stacked vertically and powered by huge motors. The motors work hard to apply extreme compression to the metal.

These mills take coils of hot-rolled, pickled products and pass them through, making them thinner. Once the metal has passed through the rolls and has reached its desired thickness, it's done being rolled but it is not quite ready for use. At this point in the process, the metal is still highly cold-worked, and while it is high strength, it can be brittle. It needs to be annealed at a higher temperature to soften the steel so it is less difficult to work with. Once the metal has been annealed, it's easier to use it in many applications, because it's able to be bent and formed.

Another method of cold rolling uses a reversing mill, which passes the strip back and forth between mandrels. This reduces the thickness of the strip during each pass until the desired thickness is reached. Metal can be reduced by between 60 and 80 percent through cold rolling, and then can be used in the creation of consumer goods or for use in other industries.